Cables

Circuit Protection

Fire & Security

Heating & Ventilation

Lamps & Lighting

Smart Systems

Solar Panels & EV Chargers

Switches and Sockets

Tools & Accessories

Cables

Twin & Earth Cables

Cables

Twin & Earth LSF Cables

Cables

Twin & Earth LSF Cables

Cables

Flex 2 Core Cables

Cables

Flex 2 Core Cables

Cables

3 Core Flex Cables

Cables

3 Core Flex Cables

Cables

Flex 4 Core Cables

Cables

Flex 4 Core Cables

Cables

3 Core Armoured Cable

Cables

3 Core Armoured Cable

Cables

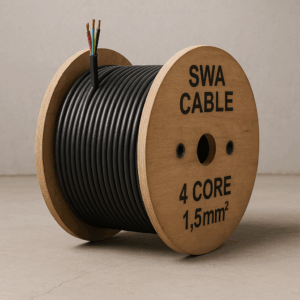

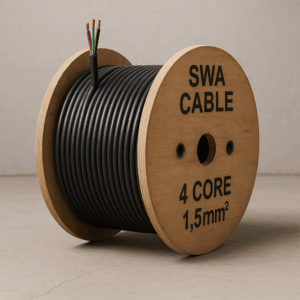

4 Core Armoured Cable

Cables

4 Core Armoured Cable

Cables

5 Core Armoured Cable

Cables

5 Core Armoured Cable

Cables

Unarmoured Power Cable

Cables

Unarmoured Power Cable

Cables

Data Cables

Cables

Data Cables

Cables

Fire Cables

Cables

Fire Cables

Cables

Single Core Cables

Cables

Single Core Cables

Cables

Meter Tails

Cables

Meter Tails

Cables

Twin & Earth Cables 1.0 mm

Cables

Twin & Earth Cables 1.5 mm

Cables

Twin & Earth Cables 1.5 mm

Cables

Twin & Earth Cables 2.5 mm

Cables

Twin & Earth Cables 2.5 mm

Cables

Twin & Earth Cables 4 mm

Cables

Twin & Earth Cables 4 mm

Cables

Twin & Earth Cables 6 mm

Cables

Twin & Earth Cables 6 mm

Cables

Twin & Earth Cables 10 mm

Cables

Twin & Earth Cables 10 mm

Cables

Twin & Earth Cables 16 mm

Cables

Twin & Earth Cables 16 mm

Cables

Twin & Earth LSF 1.0 mm

Cables

Twin & Earth LSF 1.5 mm

Cables

Twin & Earth LSF 1.5 mm

Cables

Twin & Earth LSF 2.5 mm

Cables

Twin & Earth LSF 2.5 mm

Cables

Twin & Earth LSF 4.0mm

Cables

Twin & Earth LSF 4.0mm

Cables

Twin & Earth LSF 6.0mm

Cables

Twin & Earth LSF 6.0mm

Cables

Twin & Earth LSF 10 mm

Cables

Twin & Earth LSF 10 mm

Cables

Twin & Earth LSF 16 mm

Cables

Twin & Earth LSF 16 mm

Cables

Flex 2 Core 0.50 mm

Cables

Flex 2 Core 0.75 mm

Cables

Flex 2 Core 0.75 mm

Cables

Flex 2 Core 1.00 mm

Cables

Flex 2 Core 1.00 mm

Cables

Flex 2 Core 1.5 mm

Cables

Flex 2 Core 1.5 mm

Cables

Flex 2 Core 2.5 mm

Cables

Flex 2 Core 2.5 mm

Cables

Flex 3 Core 0.75 mm

Cables

Flex 3 Core 1.00 mm

Cables

Flex 3 Core 1.00 mm

Cables

Flex 3 Core 1.50 mm

Cables

Flex 3 Core 1.50 mm

Cables

Flex 3 Core 2.50 mm

Cables

Flex 3 Core 2.50 mm

Cables

Flex 4 Core 0.75 mm

Cables

Flex 4 Core 1.00 mm

Cables

Flex 4 Core 1.00 mm

Cables

Flex 4 Core 1.5 mm

Cables

Flex 4 Core 1.5 mm

Cables

Flex 4 Core 2.5 mm

Cables

Flex 4 Core 2.5 mm

Cables

SWA 3 Core 1.5 mm

Cables

SWA 3 Core 2.5 mm

Cables

SWA 3 Core 2.5 mm

Cables

SWA 3 Core 4 mm

Cables

SWA 3 Core 4 mm

Cables

SWA 3 Core 6 mm

Cables

SWA 3 Core 6 mm

Cables

SWA 3 Core 10 mm

Cables

SWA 3 Core 10 mm

Cables

SWA 3 Core 16 mm

Cables

SWA 3 Core 16 mm

Cables

SWA 3 Core 25 mm

Cables

SWA 3 Core 25 mm

Cables

SWA 5 Core 1.5 mm

Cables

SWA 5 Core 4 mm

Cables

SWA 5 Core 4 mm

Cables

SWA 5 Core 10 mm

Cables

SWA 5 Core 10 mm

Cables

SWA 5 Core 16 mm

Cables

SWA 5 Core 16 mm

Cables

SWA 5 Core 25 mm

Cables

SWA 5 Core 25 mm

Cables

Flexi Tailes 1m 16 mm

Cables

Flexi Tails 1m 25 mm

Cables

Flexi Tails 1m 25 mm

Cables

Flexi Tails 3m 16 mm

Cables

Flexi Tails 3m 16 mm

Cables

Flexi Tails 3m 25 mm

Cables

Flexi Tails 3m 25 mm

-

6181Y 25mm² Double Insulated Single Core Cable Blue / Blue (Sold By The Meter)

£5.27 INC. VAT £4.39 EX. VAT -

6181Y 16mm² Double Insulated Single Core Cable Brown / Brown (Sold By The Meter)

£3.47 INC. VAT £2.89 EX. VAT -

6181Y 16mm² Double Insulated Single Core Cable Blue / Blue (Sold By The Meter)

£3.47 INC. VAT £2.89 EX. VAT

-

6181Y 25mm² Double Insulated Single Core Cable Blue / Blue (Sold By The Meter)

£5.27 INC. VAT £4.39 EX. VAT -

6181Y 16mm² Double Insulated Single Core Cable Brown / Brown (Sold By The Meter)

£3.47 INC. VAT £2.89 EX. VAT -

6181Y 16mm² Double Insulated Single Core Cable Blue / Blue (Sold By The Meter)

£3.47 INC. VAT £2.89 EX. VAT

-

6181Y 25mm² Double Insulated Single Core Cable Blue / Blue (Sold By The Meter)

£5.27 INC. VAT £4.39 EX. VAT -

6181Y 16mm² Double Insulated Single Core Cable Brown / Brown (Sold By The Meter)

£3.47 INC. VAT £2.89 EX. VAT -

6181Y 16mm² Double Insulated Single Core Cable Blue / Blue (Sold By The Meter)

£3.47 INC. VAT £2.89 EX. VAT

-

6181Y 25mm² Double Insulated Single Core Cable Blue / Blue (Sold By The Meter)

£5.27 INC. VAT £4.39 EX. VAT -

6181Y 16mm² Double Insulated Single Core Cable Brown / Brown (Sold By The Meter)

£3.47 INC. VAT £2.89 EX. VAT -

6181Y 16mm² Double Insulated Single Core Cable Blue / Blue (Sold By The Meter)

£3.47 INC. VAT £2.89 EX. VAT

Circuit Protection

Accessories

Circuit Protection

Consumer Units (Single Phase)

Circuit Protection

Consumer Units (Single Phase)

Circuit Protection

Distribution Boards (3 Phase)

Circuit Protection

Distribution Boards (3 Phase)

Circuit Protection

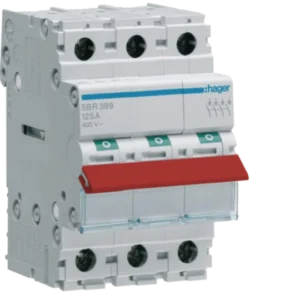

Isolators & Switch Fuses

Circuit Protection

Isolators & Switch Fuses

Circuit Protection

MCB

Circuit Protection

MCB

Circuit Protection

RCBO

Circuit Protection

RCBO

Circuit Protection

RCD (Single Phase)

Circuit Protection

RCD (Single Phase)

Circuit Protection

SPD (Single Phase)

Circuit Protection

SPD (Single Phase)

Circuit Protection

SPD (3 Phase)

Circuit Protection

SPD (3 Phase)

Circuit Protection

Switch Gear (3 Phase)

Circuit Protection

Switch Gear (3 Phase)

-

Click Elucian 44 Way Metal Dual Row Consumer Unit with 100A Mains Switch + 2 Pole SPD + 100A Connection Unit CUDEB44MSSPC39

£199.04 INC. VAT £165.87 EX. VAT -

Click Elucian 32 Way Metal Dual Row Consumer Unit with 100A Mains Switch + 2 Pole SPD + 100A Connection Unit CUDEB32MSSPC27

£170.64 INC. VAT £142.20 EX. VAT -

Click Elucian 36 Way 100A Main Switch Dual Row Consumer Unit with SPD CUDEB36MSSPC31

£184.30 INC. VAT £153.58 EX. VAT

-

Phoenix AC Surge arrester type 1+2, 1-phase, PROTECTION VAL-MS-T1/T2 335/12.5/1+1

£117.42 INC. VAT £97.85 EX. VAT -

Phoenix AC surge arrester type 1+2, 3-phase, PROTECTION VAL-MS-T1/T2 335/12.5/3+1

£103.26 INC. VAT £86.05 EX. VAT -

125A Surge Protection Kit – Hager JK102SPD

£307.36 INC. VAT £256.13 EX. VAT

-

Fuse switch disconnector 10x38, 30 A, 1000 V DC, 1-pole, DC-20B, gPV optical tripping indicator

£3.89 INC. VAT £3.24 EX. VAT -

Phoenix AC Surge arrester type 1+2, 1-phase, PROTECTION VAL-MS-T1/T2 335/12.5/1+1

£117.42 INC. VAT £97.85 EX. VAT -

Phoenix AC surge arrester type 1+2, 3-phase, PROTECTION VAL-MS-T1/T2 335/12.5/3+1

£103.26 INC. VAT £86.05 EX. VAT

-

Fuse switch disconnector 10x38, 30 A, 1000 V DC, 1-pole, DC-20B, gPV optical tripping indicator

£3.89 INC. VAT £3.24 EX. VAT -

Phoenix AC Surge arrester type 1+2, 1-phase, PROTECTION VAL-MS-T1/T2 335/12.5/1+1

£117.42 INC. VAT £97.85 EX. VAT -

Phoenix AC surge arrester type 1+2, 3-phase, PROTECTION VAL-MS-T1/T2 335/12.5/3+1

£103.26 INC. VAT £86.05 EX. VAT

-

Fuse switch disconnector 10x38, 30 A, 1000 V DC, 1-pole, DC-20B, gPV optical tripping indicator

£3.89 INC. VAT £3.24 EX. VAT -

Phoenix AC Surge arrester type 1+2, 1-phase, PROTECTION VAL-MS-T1/T2 335/12.5/1+1

£117.42 INC. VAT £97.85 EX. VAT -

Phoenix AC surge arrester type 1+2, 3-phase, PROTECTION VAL-MS-T1/T2 335/12.5/3+1

£103.26 INC. VAT £86.05 EX. VAT

-

Fuse switch disconnector 10x38, 30 A, 1000 V DC, 1-pole, DC-20B, gPV optical tripping indicator

£3.89 INC. VAT £3.24 EX. VAT -

Phoenix AC Surge arrester type 1+2, 1-phase, PROTECTION VAL-MS-T1/T2 335/12.5/1+1

£117.42 INC. VAT £97.85 EX. VAT -

Phoenix AC surge arrester type 1+2, 3-phase, PROTECTION VAL-MS-T1/T2 335/12.5/3+1

£103.26 INC. VAT £86.05 EX. VAT

Fire & Security

Carbon Monoxide

Fire & Security

Heat Alarm

Fire & Security

Heat Alarm

Fire & Security

Multi Sensor Alarm

Fire & Security

Multi Sensor Alarm

Fire & Security

Smoke Alarm

Fire & Security

Smoke Alarm

Fire & Security

CCTV

Fire & Security

CCTV

Fire & Security

Door Entry System

Fire & Security

Door Entry System

Fire & Security

Fire Alarm Systems

Fire & Security

Fire Alarm Systems

-

ESP Espire ES1CHL Carbon Monoxide and Heat Multi-Sensor Alarm Powered by a 10 Year Lithium Battery

£65.27 INC. VAT £54.39 EX. VAT -

ESP Espire Carbon Monoxide Alarm - Powered by a Sealed 10 Year Lithium Battery

£27.46 INC. VAT £22.88 EX. VAT -

ESP Espire Mains Powered Carbon Monoxide and Heat Multi-Sensor Alarm 10 Year Lithium Back-Up Battery

£75.96 INC. VAT £63.30 EX. VAT

-

ESP Espire ES1CHL Carbon Monoxide and Heat Multi-Sensor Alarm Powered by a 10 Year Lithium Battery

£65.27 INC. VAT £54.39 EX. VAT -

ESP Espire Smoke and Heat Multi-Sensor Alarm - Powered by a Sealed 10 Year Lithium

£39.85 INC. VAT £33.21 EX. VAT -

ESP Espire Optical Heat Alarm - Powered by a Sealed 10 Year Lithium Battery

£21.22 INC. VAT £17.68 EX. VAT

-

ESP Espire ES1CHL Carbon Monoxide and Heat Multi-Sensor Alarm Powered by a 10 Year Lithium Battery

£65.27 INC. VAT £54.39 EX. VAT -

ESP Espire Smoke and Heat Multi-Sensor Alarm - Powered by a Sealed 10 Year Lithium

£39.85 INC. VAT £33.21 EX. VAT -

ESP Espire Mains Powered Carbon Monoxide and Heat Multi-Sensor Alarm 10 Year Lithium Back-Up Battery

£75.96 INC. VAT £63.30 EX. VAT

-

ESP Espire Smoke and Heat Multi-Sensor Alarm - Powered by a Sealed 10 Year Lithium

£39.85 INC. VAT £33.21 EX. VAT -

ESP Espire Optical Smoke Alarm - Powered by a Sealed 10 Year Lithium Battery

£20.36 INC. VAT £16.97 EX. VAT -

ESP Espire Mains Powered Optical Smoke Alarm - with a Replaceable 9V Battery - ES1SRV

£23.44 INC. VAT £19.53 EX. VAT

-

Safety fire switch automatic reconnection of the DC circuit after AC power is restored, 4 DC strings

£180.67 INC. VAT £150.56 EX. VAT -

S-Box - Fire safety switch, 4 chains

£135.01 INC. VAT £112.51 EX. VAT -

Safety fire switch automatic reconnection of the DC circuit after AC power is restored, 2 DC strings

£137.39 INC. VAT £114.49 EX. VAT

Heating & Ventilation

Air Curtains

Heating & Ventilation

Down Flow Heaters

Heating & Ventilation

Down Flow Heaters

Heating & Ventilation

Electric Boilers

Heating & Ventilation

Electric Boilers

Heating & Ventilation

Electric Radiators

Heating & Ventilation

Electric Radiators

Heating & Ventilation

Extractor Fans

Heating & Ventilation

Extractor Fans

Heating & Ventilation

Grill & Ducting

Heating & Ventilation

Grill & Ducting

Heating & Ventilation

Heat Pumps

Heating & Ventilation

Heat Pumps

Heating & Ventilation

Infra Red Heating

Heating & Ventilation

Infra Red Heating

Heating & Ventilation

Positive Input Ventilation (PIV)

Heating & Ventilation

Positive Input Ventilation (PIV)

Heating & Ventilation

Thermostats

Heating & Ventilation

Thermostats

Heating & Ventilation

Underfloor Heating

Heating & Ventilation

Underfloor Heating

Lamps & Lighting

Battens

Lamps & Lighting

Bezels

Lamps & Lighting

Bezels

Lamps & Lighting

Bulbs

Lamps & Lighting

Bulbs

Lamps & Lighting

Bulkheads

Lamps & Lighting

Bulkheads

Lamps & Lighting

Control Gear & PIR

Lamps & Lighting

Control Gear & PIR

Lamps & Lighting

Corston

Lamps & Lighting

Corston

Lamps & Lighting

Downlight Accessories

Lamps & Lighting

Downlight Accessories

Lamps & Lighting

Drivers

Lamps & Lighting

Drivers

Lamps & Lighting

Emergency Lighting

Lamps & Lighting

Emergency Lighting

Lamps & Lighting

Garden Lights

Lamps & Lighting

Garden Lights

Lamps & Lighting

GU10 Downlights

Lamps & Lighting

GU10 Downlights

Lamps & Lighting

GU10 Lamps

Lamps & Lighting

GU10 Lamps

Lamps & Lighting

LED Downlights

Lamps & Lighting

LED Downlights

Lamps & Lighting

LED Panels

Lamps & Lighting

LED Panels

Lamps & Lighting

LED Strips

Lamps & Lighting

LED Strips

Lamps & Lighting

Mains Voltage Downlights

Lamps & Lighting

Mains Voltage Downlights

Lamps & Lighting

Pendant Lights

Lamps & Lighting

Pendant Lights

Lamps & Lighting

Under Cabinet Lights

Lamps & Lighting

Under Cabinet Lights

Lamps & Lighting

Wall Lights

Lamps & Lighting

Wall Lights

-

Energy efficient IP65 rated integrated LED round bulkhead suitable for ceiling and wall mounting.

£13.19 INC. VAT £10.99 EX. VAT -

Melana CCT & Wattage Adjustable LED IP65 Outdoor Bulkhead

£22.79 INC. VAT £18.99 EX. VAT -

ALL LED Romano 13W IP65 CCT Selectable Oval Utility Bulkhead

£12.72 INC. VAT £10.60 EX. VAT

Lamps & Lighting

Wall Lights

Lamps & Lighting

Picture Lights

Lamps & Lighting

Picture Lights

Lamps & Lighting

Spotlights & Downlights

Lamps & Lighting

Spotlights & Downlights

Lamps & Lighting

Pendant Lights

Lamps & Lighting

Pendant Lights

Lamps & Lighting

Garden Lighting

Lamps & Lighting

Garden Lighting

Lamps & Lighting

Bathroom Lighting

Lamps & Lighting

Bathroom Lighting

-

ALL LED Osprey 50W Carbon Black IP65 CCT Selectable Flood Light With Q-Nex Plug And Play Technology

£32.86 INC. VAT £27.38 EX. VAT -

ALL LED Osprey 30W Carbon Black IP65 CCT Selectable Flood Light With Q-Nex Plug And Play Technology

£25.54 INC. VAT £21.28 EX. VAT -

ALL LED Osprey 20W Carbon Black IP65 CCT Selectable Flood Light With Q-Nex Plug And Play Technology

£21.88 INC. VAT £18.23 EX. VAT

Solar Panels & EV Chargers

Battery Storage

Solar Panels & EV Chargers

EV Chargers

Solar Panels & EV Chargers

EV Chargers

Solar Panels & EV Chargers

EV Chargers Accessories

Solar Panels & EV Chargers

EV Chargers Accessories

Solar Panels & EV Chargers

Inverters

Solar Panels & EV Chargers

Inverters

Solar Panels & EV Chargers

Meters

Solar Panels & EV Chargers

Meters

Solar Panels & EV Chargers

Mounting Equipment

Solar Panels & EV Chargers

Mounting Equipment

Solar Panels & EV Chargers

Solar Charge Controllers

Solar Panels & EV Chargers

Solar Charge Controllers

Solar Panels & EV Chargers

Solar Panels

Solar Panels & EV Chargers

Solar Panels

-

Combiner box with DEHN 1000V DC surge arrester type 1+2, 2x PV string, 2x MPPT, 4x overvoltage protections. 25A, 2x DC 4P distribution, 32A 1000V

£303.17 INC. VAT £252.64 EX. VAT -

Combiner box with DC OBO 1000V surge arrester type 2, 2x PV string, 2x MPPT

£78.70 INC. VAT £65.58 EX. VAT -

DC combiner box with 1000V surge arrester type 2, 2x PV string, 2x MPPT, fuse 4x15A

£146.58 INC. VAT £122.15 EX. VAT

-

PHOTOVOLTAIC MODULE LONGI 440W, HI-MO 7, MONOCRYSTALLINE, BLACK FRAME, BIFACIAL, FRAME 30 MM, CONECTOR EVO2, CABEL 1200MM

£68.83 INC. VAT £57.36 EX. VAT -

Photovoltaic module trina 510W, vertex s+, half-cut, black frame, frame 30 mm, 1300 cable

£74.69 INC. VAT £62.24 EX. VAT -

Photovoltaic module Longi 440W, Hi-MO X6 Explorer, monocristalline, black frame, white backsheet, frame 30mm, connector EVO2, cable 1200mm

£76.69 INC. VAT £63.91 EX. VAT

Switches and Sockets

Corston

Switches and Sockets

5 Amp Sockets

Switches and Sockets

5 Amp Sockets

Switches and Sockets

Blanking Plates

Switches and Sockets

Blanking Plates

Switches and Sockets

Cooker Switch

Switches and Sockets

Cooker Switch

Switches and Sockets

Dimmer Switches

Switches and Sockets

Dimmer Switches

Switches and Sockets

Euro Modules & Grid Switches

Switches and Sockets

Euro Modules & Grid Switches

Switches and Sockets

Euro Plates

Switches and Sockets

Euro Plates

Switches and Sockets

Faceplates

Switches and Sockets

Faceplates

Switches and Sockets

Fan Isolator

Switches and Sockets

Fan Isolator

Switches and Sockets

Fused Spurs

Switches and Sockets

Fused Spurs

Switches and Sockets

Light Switches

Switches and Sockets

Light Switches

Switches and Sockets

Metal Clad Switches & Sockets

Switches and Sockets

Metal Clad Switches & Sockets

Switches and Sockets

Moulded Switches & Sockets

Switches and Sockets

Moulded Switches & Sockets

Switches and Sockets

Network Sockets

Switches and Sockets

Network Sockets

Switches and Sockets

Outdoor Sockets

Switches and Sockets

Outdoor Sockets

Switches and Sockets

Plug Sockets

Switches and Sockets

Plug Sockets

Switches and Sockets

Pull Cords

Switches and Sockets

Pull Cords

Switches and Sockets

Shaver Sockets

Switches and Sockets

Shaver Sockets

Switches and Sockets

TV Sockets

Switches and Sockets

TV Sockets

Switches and Sockets

USB Sockets

Switches and Sockets

USB Sockets

Switches and Sockets

Brass Bronze | Black

Switches and Sockets

Antique Brass | Black

Switches and Sockets

Antique Brass | Black

Switches and Sockets

Antique Brass | White

Switches and Sockets

Antique Brass | White

Switches and Sockets

Brass Polished Nickel | Black

Switches and Sockets

Brass Polished Nickel | Black

Switches and Sockets

Brass Polished Nickel | White

Switches and Sockets

Brass Polished Nickel | White

Switches and Sockets

Clear Bronze | Black

Switches and Sockets

Clear Bronze | Black

Switches and Sockets

Clear Antique Brass | White

Switches and Sockets

Clear Antique Brass | White

Switches and Sockets

Clear Polished Nickel | Black

Switches and Sockets

Clear Polished Nickel | Black

Switches and Sockets

Clear Polished Nickel | White

Switches and Sockets

Clear Polished Nickel | White

Switches and Sockets

Paintable Bronze | Black

Switches and Sockets

Paintable Bronze | Black

Switches and Sockets

Paintable Antique Brass | White

Switches and Sockets

Paintable Antique Brass | White

Switches and Sockets

Paintable Polished Nickel | Black

Switches and Sockets

Paintable Polished Nickel | Black

Switches and Sockets

Paintable Polished Nickel | White

Switches and Sockets

Paintable Polished Nickel | White

Switches and Sockets

5 Amp Sockets

Flat Plate

Brushed Brass

Switches and Sockets

5 Amp Sockets

Flat Plate

Brushed Chrome

Switches and Sockets

5 Amp Sockets

Flat Plate

Brushed Chrome

Switches and Sockets

5 Amp Sockets

Screwless

Antique Brass

Switches and Sockets

5 Amp Sockets

Screwless

Brushed Chrome

Switches and Sockets

5 Amp Sockets

Screwless

Brushed Chrome

Switches and Sockets

5 Amp Sockets

Screwless

Matt Black

Switches and Sockets

5 Amp Sockets

Screwless

Matt Black

Switches and Sockets

5 Amp Sockets

Screwless

Matt White

Switches and Sockets

5 Amp Sockets

Screwless

Matt White

Switches and Sockets

5 Amp Sockets

Screwless

Smoke Bronze

Switches and Sockets

5 Amp Sockets

Screwless

Smoke Bronze

Switches and Sockets

Blanking Plates

Flat Plate

Brushed Brass

Switches and Sockets

Blanking Plates

Flat Plate

Brushed Chrome

Switches and Sockets

Blanking Plates

Flat Plate

Brushed Chrome

Switches and Sockets

Blanking Plates

Screwless

Antique Brass

Switches and Sockets

Blanking Plates

Screwless

Brushed Chrome

Switches and Sockets

Blanking Plates

Screwless

Brushed Chrome

Switches and Sockets

Blanking Plates

Screwless

Matt Black

Switches and Sockets

Blanking Plates

Screwless

Matt Black

Switches and Sockets

Blanking Plates

Screwless

Matt White

Switches and Sockets

Blanking Plates

Screwless

Matt White

Switches and Sockets

Blanking Plates

Screwless

Smoke Bronze

Switches and Sockets

Blanking Plates

Screwless

Smoke Bronze

Switches and Sockets

Cooker Switch

Screwless

Antique Brass

Switches and Sockets

Cooker Switch

Screwless

Brushed Chrome

Switches and Sockets

Cooker Switch

Screwless

Brushed Chrome

Switches and Sockets

Cooker Switch

Screwless

Matt Black

Switches and Sockets

Cooker Switch

Screwless

Matt Black

Switches and Sockets

Cooker Switch

Screwless

Matt White

Switches and Sockets

Cooker Switch

Screwless

Matt White

Switches and Sockets

Cooker Switch

Screwless

Smoke Bronze

Switches and Sockets

Cooker Switch

Screwless

Smoke Bronze

Switches and Sockets

Dimmer Switches

Screwless

Antique Brass

Switches and Sockets

Dimmer Switches

Screwless

Brushed Chrome

Switches and Sockets

Dimmer Switches

Screwless

Brushed Chrome

Switches and Sockets

Dimmer Switches

Screwless

Matt Black

Switches and Sockets

Dimmer Switches

Screwless

Matt Black

Switches and Sockets

Dimmer Switches

Screwless

Matt White

Switches and Sockets

Dimmer Switches

Screwless

Matt White

Switches and Sockets

Dimmer Switches

Screwless

Smoke Bronze

Switches and Sockets

Dimmer Switches

Screwless

Smoke Bronze

Switches and Sockets

Dimmer Switches

Screwless

Polished Brass

Switches and Sockets

Dimmer Switches

Screwless

Polished Brass

Switches and Sockets

Dimmer Switches

Screwless

Polished Chrome

Switches and Sockets

Dimmer Switches

Screwless

Polished Chrome

Switches and Sockets

Euro Modules & Grid Switches

Screwless

Brushed Chrome

Switches and Sockets

Euro Modules & Grid Switches

Screwless

Matt Black

Switches and Sockets

Euro Modules & Grid Switches

Screwless

Matt Black

Switches and Sockets

Euro Modules & Grid Switches

Screwless

Matt White

Switches and Sockets

Euro Modules & Grid Switches

Screwless

Matt White

Switches and Sockets

Euro Plates

Screwless

Brushed Chrome

Switches and Sockets

Euro Plates

Screwless

Matt Black

Switches and Sockets

Euro Plates

Screwless

Matt Black

Switches and Sockets

Euro Plates

Screwless

Matt White

Switches and Sockets

Euro Plates

Screwless

Matt White

Switches and Sockets

Euro Plates

Screwless

Smoke Bronze

Switches and Sockets

Euro Plates

Screwless

Smoke Bronze

Switches and Sockets

Faceplates

Flat Plate

Brushed Brass

Switches and Sockets

Faceplates

Flat Plate

Brushed Chrome

Switches and Sockets

Faceplates

Flat Plate

Brushed Chrome

Switches and Sockets

Faceplates

Flat Plate

Polished Chrome

Switches and Sockets

Faceplates

Flat Plate

Polished Chrome

Switches and Sockets

Faceplates

Screwless

Brushed Chrome

Switches and Sockets

Faceplates

Screwless

Matt Black

Switches and Sockets

Faceplates

Screwless

Matt Black

Switches and Sockets

Faceplates

Screwless

Matt White

Switches and Sockets

Faceplates

Screwless

Matt White

Switches and Sockets

Faceplates

Screwless

Polished Chrome

Switches and Sockets

Faceplates

Screwless

Polished Chrome

Switches and Sockets

Faceplates

Screwless

Smoke Bronze

Switches and Sockets

Faceplates

Screwless

Smoke Bronze

Switches and Sockets

Fan Isolator

Screwless

Brushed Chrome

Switches and Sockets

Fan Isolator

Screwless

Matt Black

Switches and Sockets

Fan Isolator

Screwless

Matt Black

Switches and Sockets

Fan Isolator

Screwless

Matt White

Switches and Sockets

Fan Isolator

Screwless

Matt White

Switches and Sockets

Fan Isolator

Screwless

Polished Chrome

Switches and Sockets

Fan Isolator

Screwless

Polished Chrome

Switches and Sockets

Fan Isolator

Screwless

Smoke Bronze

Switches and Sockets

Fan Isolator

Screwless

Smoke Bronze

Switches and Sockets

Fused Spurs

Screwless

Brushed Chrome

Switches and Sockets

Fused Spurs

Screwless

Matt Black

Switches and Sockets

Fused Spurs

Screwless

Matt Black

Switches and Sockets

Fused Spurs

Screwless

Matt White

Switches and Sockets

Fused Spurs

Screwless

Matt White

Switches and Sockets

Fused Spurs

Screwless

Polished Brass

Switches and Sockets

Fused Spurs

Screwless

Polished Brass

Switches and Sockets

Fused Spurs

Screwless

Polished Chrome

Switches and Sockets

Fused Spurs

Screwless

Polished Chrome

Switches and Sockets

Fused Spurs

Screwless

Smoke Bronze

Switches and Sockets

Fused Spurs

Screwless

Smoke Bronze

Switches and Sockets

Light Switches

Screwless

Brushed Chrome

Switches and Sockets

Light Switches

Screwless

Matt Black

Switches and Sockets

Light Switches

Screwless

Matt Black

Switches and Sockets

Light Switches

Screwless

Matt White

Switches and Sockets

Light Switches

Screwless

Matt White

Switches and Sockets

Light Switches

Screwless

Smoke Bronze

Switches and Sockets

Light Switches

Screwless

Smoke Bronze

Switches and Sockets

Network Sockets

Screwless

Brushed Chrome

Switches and Sockets

Network Sockets

Screwless

Matt Black

Switches and Sockets

Network Sockets

Screwless

Matt Black

Switches and Sockets

Network Sockets

Screwless

Matt White

Switches and Sockets

Network Sockets

Screwless

Matt White

Switches and Sockets

Network Sockets

Screwless

Smoke Bronze

Switches and Sockets

Network Sockets

Screwless

Smoke Bronze

Switches and Sockets

Plug Sockets

Flat Plate

One Gang

Switches and Sockets

Plug Sockets

Flat Plate

Two Gang

Switches and Sockets

Plug Sockets

Flat Plate

Two Gang

Switches and Sockets

Plug Sockets

Screwless

One Gang

Switches and Sockets

Plug Sockets

Screwless

Two Gang

Switches and Sockets

Plug Sockets

Screwless

Two Gang

Switches and Sockets

Shaver Sockets

Flat Plate

Brushed Chrome

Switches and Sockets

Shaver Sockets

Flat Plate

Polished Chrome

Switches and Sockets

Shaver Sockets

Flat Plate

Polished Chrome

Switches and Sockets

Shaver Sockets

Screwless

Brushed Chrome

Switches and Sockets

Shaver Sockets

Screwless

Matt Black

Switches and Sockets

Shaver Sockets

Screwless

Matt Black

Switches and Sockets

Shaver Sockets

Screwless

Matt White

Switches and Sockets

Shaver Sockets

Screwless

Matt White

Switches and Sockets

Shaver Sockets

Screwless

Polished Chrome

Switches and Sockets

Shaver Sockets

Screwless

Polished Chrome

Switches and Sockets

Shaver Sockets

Screwless

Smoke Bronze

Switches and Sockets

Shaver Sockets

Screwless

Smoke Bronze

Switches and Sockets

TV Sockets

Screwless

Brushed Chrome

Switches and Sockets

TV Sockets

Screwless

Matt Black

Switches and Sockets

TV Sockets

Screwless

Matt Black

Switches and Sockets

TV Sockets

Screwless

Matt White

Switches and Sockets

TV Sockets

Screwless

Matt White

Switches and Sockets

TV Sockets

Screwless

Smoke Bronze

Switches and Sockets

TV Sockets

Screwless

Smoke Bronze

Switches and Sockets

USB Sockets

Flat Plate

Brushed Brass

Switches and Sockets

USB Sockets

Flat Plate

Brushed Chrome

Switches and Sockets

USB Sockets

Flat Plate

Brushed Chrome

Switches and Sockets

USB Sockets

Flat Plate

Polished Chrome

Switches and Sockets

USB Sockets

Flat Plate

Polished Chrome

Switches and Sockets

USB Sockets

Screwless

Brushed Chrome

Switches and Sockets

USB Sockets

Screwless

Matt Black

Switches and Sockets

USB Sockets

Screwless

Matt Black

Switches and Sockets

USB Sockets

Screwless

Matt White

Switches and Sockets

USB Sockets

Screwless

Matt White

-

![Screwless 1G Dual USB-C and USB-A Charger Plate [20V DC 63W] - Antique Brass](https://cewgroup.co.uk/wp-content/uploads/2025/05/1939966-autocrop-1196x1200-1-300x300.png)

Screwless 1G Dual USB-C and USB-A Charger Plate [20V DC 63W] - Antique Brass

£76.74 INC. VAT £63.95 EX. VAT -

![Screwless 13A 2G DP Switched Socket with Dual USB-C [65W DUAL FASTCHARGE] - Antique Brass](https://cewgroup.co.uk/wp-content/uploads/2025/05/2039442-autocrop-1200x713-1-300x300.png)

Screwless 13A 2G DP Switched Socket with Dual USB-C [65W DUAL FASTCHARGE] - Antique Brass

£65.99 INC. VAT £54.99 EX. VAT -

Screwless 13A 2G DP Switched Socket with Dual USB A+C 20V DC 2.25A (Max. 45W) - Antique Brass

£62.56 INC. VAT £52.13 EX. VAT

Tools & Accessories

Back Boxes

Tools & Accessories

Cable Clips

Tools & Accessories

Cable Clips

Tools & Accessories

Cable Glands

Tools & Accessories

Cable Glands

Tools & Accessories

Cable Tools

Tools & Accessories

Cable Tools

Tools & Accessories

Connectors

Tools & Accessories

Connectors

Tools & Accessories

Drill Bits

Tools & Accessories

Drill Bits

Tools & Accessories

Extensions Leads

Tools & Accessories

Extensions Leads

Tools & Accessories

Holesaws & Arbors

Tools & Accessories

Holesaws & Arbors

Tools & Accessories

Insulation Tapes

Tools & Accessories

Insulation Tapes

Tools & Accessories

Junction Boxes

Tools & Accessories

Junction Boxes

Tools & Accessories

Multi Tools Blades

Tools & Accessories

Multi Tools Blades

Tools & Accessories

Pattress Boxes

Tools & Accessories

Pattress Boxes

Tools & Accessories

Pliers

Tools & Accessories

Pliers

Tools & Accessories

Rubber Grommets

Tools & Accessories

Rubber Grommets

Tools & Accessories

Screwdrivers

Tools & Accessories

Screwdrivers

Tools & Accessories

Test Equipment

Tools & Accessories

Test Equipment

Tools & Accessories

Tool Bags

Tools & Accessories

Tool Bags

-

Inverter GoodWe 10kW, hybrid, three-phase, AFCI, SPD II, LAN, WIFI, Bluetooth, RS485, with CT 90A

£1,502.42 INC. VAT £1,252.02 EX. VAT -

Inverter GoodWe 8kW, hybrid, three-phase, AFCI, SPD II, LAN, WIFI, Bluetooth, RS485, with CT 90A

£1,381.31 INC. VAT £1,151.09 EX. VAT -

Inverter GoodWe 6kW, hybrid, three-phase, AFCI, SPD II, LAN, WIFI, Bluetooth, RS485, with CT 90A

£1,352.74 INC. VAT £1,127.28 EX. VAT